Bamboo processing equipment help in the manufacture of bamboo goods. Bamboo is principally utilized for dwelling-designed presents and objects like bamboo baskets, paper cups and bamboo vases etc. Bamboo can be employed for generating bamboo household furniture. This is often an eco-welcoming materials that's quick gaining recognition all over the environment.

Bamboo output involves the mechanical processing of turning bamboo fibers into thread, yarn, and bamboo blades. After this, these solutions is usually more utilized for different needs. Bamboo fiber is principally utilized for producing outfits, sweaters and bed sheets etc. Bamboo blades are employed for sawing wood and generating paper and cardboards. These products and solutions are ready with enable of a Bamboo Equipment.

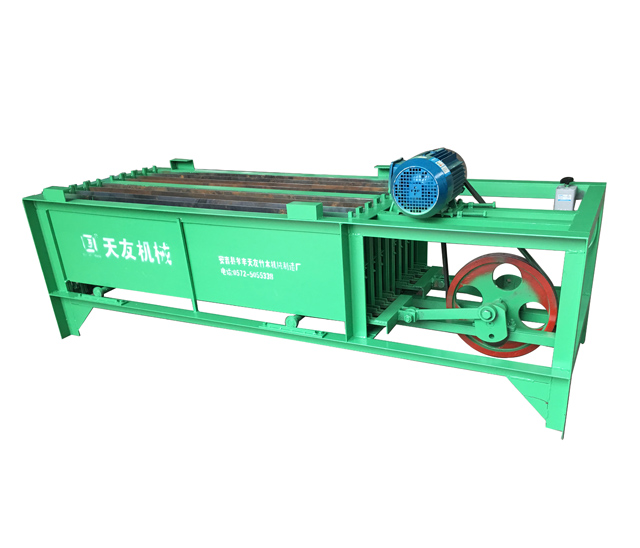

The Bamboo Machine is divided into two sorts particularly, the immediate and indirect Bamboo Machine. The immediate Bamboo Machine features a cutter head as well as a conveyor. Bamboo fabric is fed through the conveyor and on to the cutter head. Since the Bamboo material passes from the cutter head it's Minimize into wished-for dimension. Bamboo strips of different thicknesses can be ordered from any Bamboo supplier.

The next variety of Bamboo Device will be the indirect Bamboo Equipment. This machine is much like the utility model of Bamboo but with no bamboo material. The cuttings originate from possibly a belt or from a knife relaxation. Bamboo material is handed with the knife relaxation and on to your belt, and that is then operate in excess of a pulley. When the belt passes above the knife rest then it slices the Bamboo into the desired size.

The third form of Bamboo Machine is the conveying roller ongoing feed method is cut open the bamboo device by sliding the knife rest into your machine. The thin bamboo tube is placed in the machine as well as knife rests are slid in the tube. Bamboo strips of various thicknesses are fed in the equipment through the knife rest. Bamboo cloth is fed with the tube and onto the belt, which are then run above a pulley. Bamboo strips of various thicknesses are then sliced on to the belt by the belt as it truly is rolled across the belt. This Bamboo Equipment is much more well-liked as opposed to utility model of Bamboo.

Bamboo slabs and blocks are fed in to the four aspect planer by slender belts. Bamboo strips along with the blocks are sliced to the 4 aspect planer with the external knot mechanism. This Bamboo Machine could be the quickest Bamboo producing machine build. The four aspect planer plus the exterior knot mechanism slice the Bamboo into Bamboo strips and Bamboo blocks evenly and with no slippage.

The fourth style of Bamboo equipment will be the 4 aspect planer Bamboo cutter. This Bamboo machine is different through the a few kinds Click here for more info of Bamboo explained previously mentioned. It's a entrance conclusion feed cutter and also a back conclusion slimmer cutter. Bamboo slabs and blocks are fed to the entrance conclusion of your Bamboo cutter by slim belts. Bamboo fabric is handed with the entrance end from the Bamboo cutter, when the fiber slabs and blocks are sliced on to the belt through the slimmer system.

The last Bamboo Device is easily the most intriguing Bamboo equipment because it combines all the Bamboo Equipment into a single Bamboo splitter. This Bamboo splitter has 4 cutting mechanisms that operate concurrently. The first system cuts through the skinny bamboo strips. Bamboo material passes in the cutting system as well as the fiber strip is Slash into Bamboo strips based on the size from the machine's letterhead. Then, the remaining Bamboo content is passed through a conveying roller and the Bamboo fiber is collected in the entrance end of your acquiring unit.

Bamboo manufacturing is developing at a tremendous charge in the final 10 years. Bamboo producing is a strategy of gathering and chopping Bamboo into various products which include Bamboo Shoe, Bamboo Flooring, Bamboo Furnishings, Bamboo Mattress, Bamboo Stool, Bamboo Chair and Bamboo Panels. Bamboo has lots of benefits over common lumber trees that happen to be a lot more environmentally accountable. As Bamboo grows more rapidly than trees it won't be To put it briefly source and Bamboo merchandise will likely be readily available.

To create Bamboo items There's two generation methods used, either throughout the utilization of a Compressed Air Mould or even a Dry Sinking or Vacuum Mould. A normal Bamboo Board manufacturing generation line system starts with a large-speed horizontal cross-Lower observed slicing a brief size of Bamboo fiber plank. The Bamboo board is placed on a drying platform that circulates drinking water containing silica that can help dampness evaporate in the Bamboo plank and press out the shrinking edges of Bamboo fiber plank. Bamboo is then sliced with hand knives into uniform lengths and also the pieces are pulled by means of an assortment of sawing motions. Several different grinding tools and grinding wheels are utilized to more polish the surfaces of Bamboo parts.

Just after Bamboo boards are Reduce and trimmed to wanted lengths, They're then laid horizontally to be Bamboo Shoe or Bamboo Flooring. Inside the Bamboo Flooring production line, a Bamboo Shoe is ready by passing two circular observed blades through the boards to make a cross-hatched sample. This pattern is exactly what varieties the Bamboo Flooring panels. A number of grinding tools and grinding wheels are used to even more polish the surfaces with the Bamboo Flooring panels. As soon as the Bamboo Shoe/Bamboo Flooring is done the Bamboo is packaged in its respective strips plus the strips are bundled alongside one another.

To help in Bamboo Door-plate manufacture; a thin, but strong, bamboo Wooden is Slice into workable sizes. The Lower bamboo Wooden is then placed on a heated chrome steel floor that is definitely earlier mentioned a drinking water reservoir. The heated bamboo Wooden doorway-plate substance is put into your heating system. This Bamboo Doorway-plate substance is then permitted to cure to achieve its unique moisture content. The moment cured, the Bamboo door-plate is then inserted to the utility product thus forming the Bamboo door-plate and also Bamboo Flooring into its respective utility designs.

Right after Bamboo boards are formed into Bamboo doorway-plate and Bamboo flooring, the Bamboo door-plate and Bamboo flooring are then pressed alongside one another into only one Bamboo molding unit. The Bamboo molding device is then still left to dry right until it yields to your firm and strong Bamboo panel. If the Bamboo panel has dried to some firm and good condition, the Bamboo molding unit is pulled from your drying Bamboo panel. The Bamboo molding unit is then still left to dry on its own for an additional eighteen hours. This Bamboo molding is then utilized to build the Bamboo doorway-panels that comprise the utility model of your Bamboo product or service. After the Bamboo door-panels have dried to some agency and sound state the Bamboo doorway-panels are again pressurized into their respective utility styles.

Inside the Bamboo door-plate and Bamboo flooring software, Bamboo items are milled in accordance with the utility model that They are going to be used in. As soon as the Bamboo components are milled to the right utility design which the Bamboo manufacturing line are going to be applying, the Bamboo products are then pressed into their respective moldings. The presses accustomed to press the Bamboo resources into their moldings are referred to as "expander push" strategies. Pressurizing the Bamboo resources into their moldings using these Expander press solutions yield Bamboo panels that are dependable in sizing, constant in color and reliable in shape. This constant Bamboo dimensions, shade and condition all over all Bamboo doorway-plate and Bamboo flooring production solutions is exactly what will make Bamboo so desirable.

Bamboo doorways and Bamboo floors have now been launched to the marketplace with the explained Bamboo Study and Growth Company of India, Ltd., and that is also normally known as BGC. Bamboo doors and Bamboo flooring have long been in Dr. Premalatha's (who is likewise the founder of Bamboo Global Buying and selling Company) list of products that He's most pleased with. Bamboo International Trading Corporation or BGC is led by Dr. Premalatha, who's the only real particular person from Bamboo World-wide Buying and selling Company's roster who may have experienced any prior working experience while in the manufacture and creation of Bamboo goods. Bamboo Worldwide Trading Company has also released a whole line of Bamboo relevant items that utilizes Dr. Premalatha's name on them.

Bamboo doorways and Bamboo flooring have verified being extremely popular globally. With lots of international locations, industries, colleges and perhaps households using notice of Bamboo's Gains and marveling at its splendor, Bamboo production has grown remarkably. Bamboo continues to be when compared with Wooden since it is much stronger than most other woods available on the market currently. Bamboo has also demonstrated anti-allergenic Homes, contrary to most other woods, which also makes Bamboo perfect for use in applications for example Bed room home furniture and rest room vanity units. Bamboo output is set to expand and extend fast, so the long run for Bamboo appears to be like as brilliant given that the sky.